The Challenge

Eliminate toxic wastewater without increasing costs

China has made water conservation a key priority and is ramping up regulations around wastewater discharge, limiting both the concentration of contaminants and discharge volume. Industrial wastewater treatment is a crucial but oftentimes expensive process. A lithium iron phosphate (LFP) cathode manufacturing facility in the Hubei province of central China needed a cost-effective, high-performing solution to treat its wastewater for reuse while producing this critical component used in electric vehicles around the world.

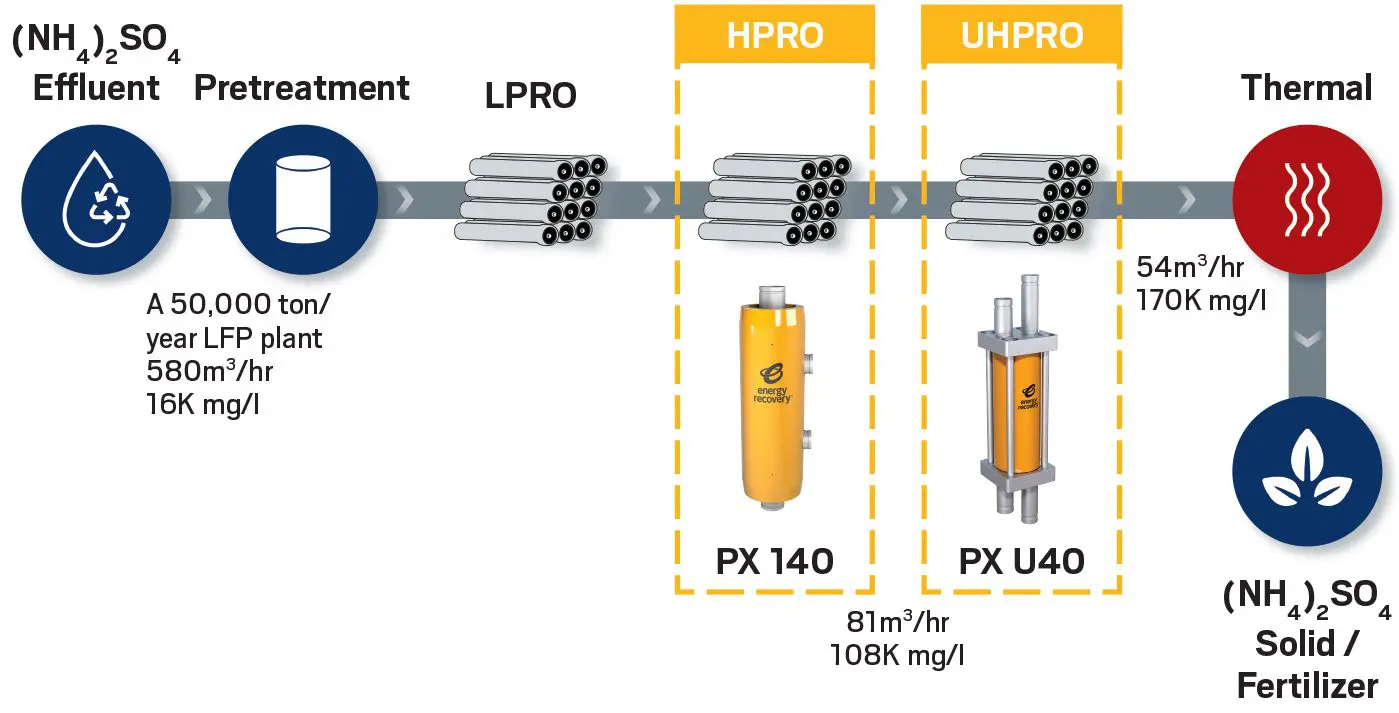

The site produces 50,000 tons of LFP per year for large lithium iron batterymanufacturers, resulting in a combined waste stream with approximately 16,000 mg/L of ammonium sulfate and periodic slugs of ammonium phosphate. To tackle this problem, the facility enlisted Sinochem Memtech Co., Ltd, a subsidiary of Sinochem International and an innovative enterprise focusing on membrane product solutions for the water treatment industry, to design a treatment facility, using a combination of technologies to pretreat the waste stream. By employing two reverse osmosis (RO) stages and an ultra high-pressure reverse osmosis (UHPRO) stage, Sinochem reduced the process flow rate by 90%, before using a thermal process on the remaining flow to reach zero liquid discharge (ZLD). However, these critical processes would normally require high energy consumption, making it harder to achieve cleaner operations without incurring prohibitively high costs.