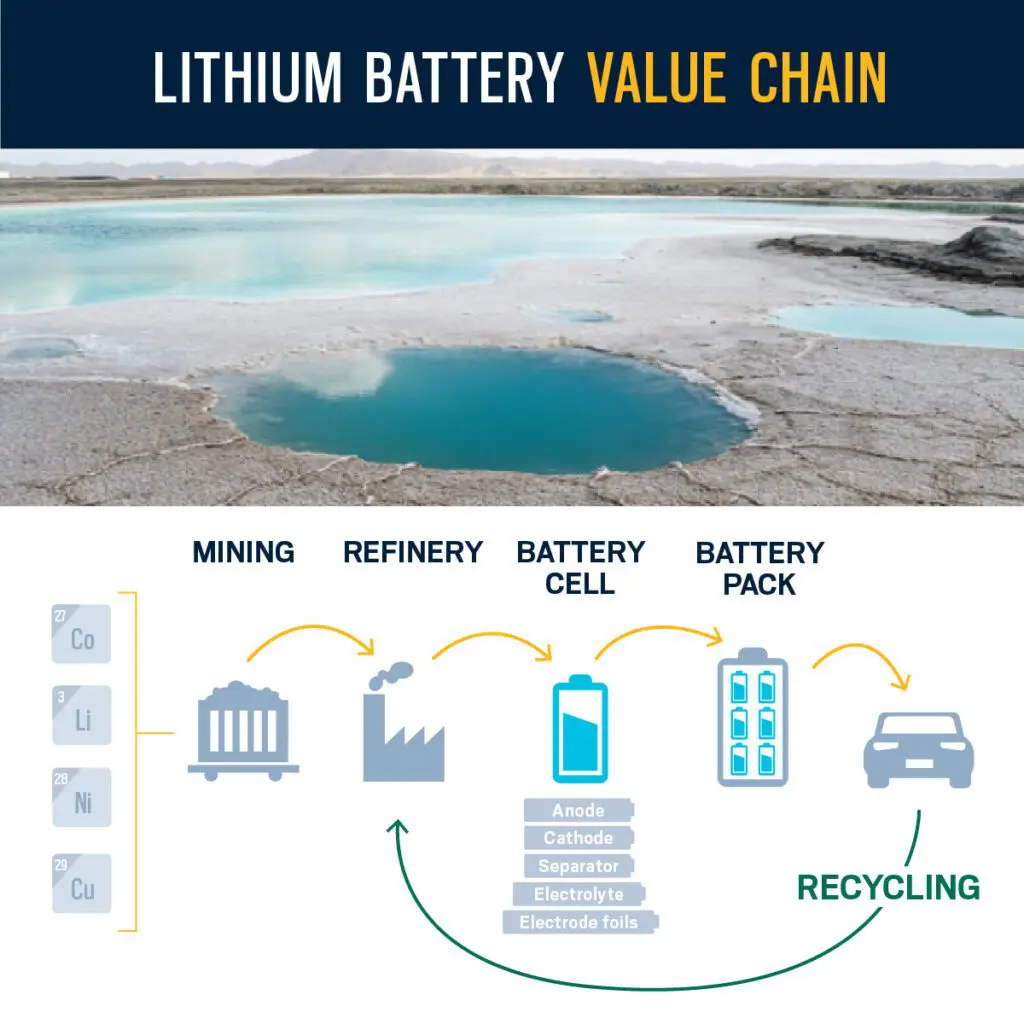

Lithium demand is expected to rise rapidly to serve the energy transition, especially for battery production. Extracting and processing lithium can be highly water and energy-intensive, in some cases requiring limits on wastewater discharge to meet environmental regulations. Reverse osmosis (RO) with PX® Pressure Exchanger® technology can boost energy savings at multiple points across the lithium battery value chain to enable lower cost, more efficient lithium extraction, and sustainable wastewater treatment.

Applications

- LFP cathode manufacturing

- Battery recycling

- Lithium brine mining, including direct lithium extraction (DLE) and non-DLE

Benefits

- Reduce capital expenses

- Lower energy use and operating costs

- Comply with environmental regulations

- Pressure and temperature recovery

In lithium applications, the PX reduces the energy consumption of reverse osmosis to separate lithium from brine, recover resources in battery recycling plants or treat wastewater from lithium battery manufacturing plants. The entire PX product family is currently installed and operating in lithium brine mining, LFP cathode manufacturing, and battery recycling applications to lower operational energy costs.

Download the full brochure and find out how the PX can reduce energy consumption for lithium applications.