The Challenge

At the center of Guangdong’s bustling textile manufacturing corridor, the Jialida Textile CETP plays a critical role in enabling regional economic growth while meeting increasingly strict wastewater discharge mandates. The facility treats effluent from a collective of textile producers using membrane-based processes and recovers fresh water, sodium chlorine, and sodium sulfate for resale.

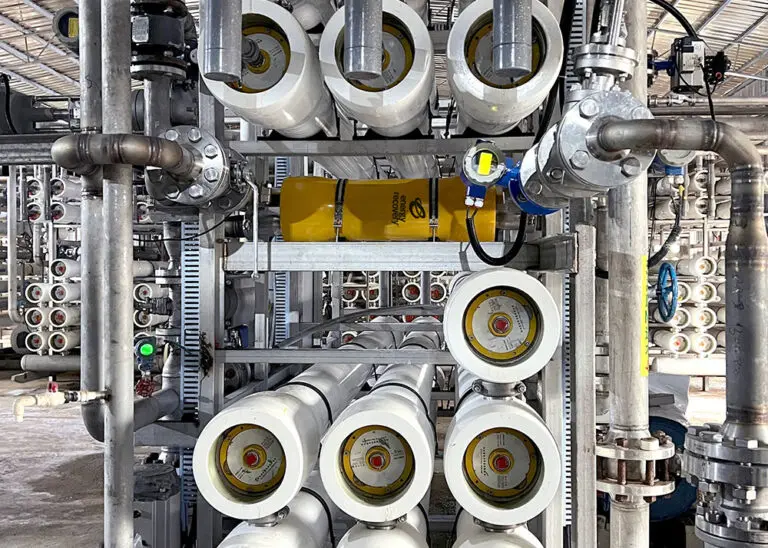

Membrane technologies such as nanofiltration (NF) and reverse osmosis (RO) systems used at the plant are efficient in concentrating wastewaters, but they require high levels of electricity at high salinities such as in ZLD applications. To achieve both environmental and economic sustainability, Jialida required a high-efficiency, high-reliability energy recovery solution that could be integrated into its existing infrastructure.

Jialida faced rising energy costs and increasing environmental pressures as Guangdong’s textile industry came under stricter regulatory oversight. The plant needed to meet more demanding effluent treatment and ZLD requirements while managing sharply increasing energy consumption from high-pressure membrane systems. Traditional high-pressure pumps could no longer keep operating costs under control as system loads grew, making it essential to find a better solution. Recovering wasted pressure energy from the NF and RO brine streams proved to be the most effective way to reduce overall energy use without sacrificing treatment performance.