Reducing Energy Costs in Desalination and Wastewater Treatment

Energy Recovery’s PX Pressure Exchanger Q Series is a range of energy recovery devices that optimize high-pressure seawater reverse osmosis (SWRO) and wastewater treatment systems over various flow ranges for maximum energy savings of up to 60%. Our leading pressure exchangers include the gold standard PX Q400, which delivers best-in-class performance and efficiency with low operational sound levels.

The PX Q Series of energy recovery devices delivers industry-leading uptime and energy savings, is designed for flexible operation, and can be paired with Energy Recovery’s high-pressure pumps and circulation pumps to maximize efficiency and operational savings.

At a Glance

Highly efficient

Peak efficiency of 98%, optimized for a wide range of pressure levels up to 83 bar (1,200 psi). Operates with concentrate flow from 4.5-90.9 m3/h (20-400 gpm).

Reliable

Industry-leading 30-year design life and 99.8% uptime

Quiet Performance

Operates at low sound levels

Low Mixing

Low volumetric mixing, including our PX Q400 which offers <3% volumetric mixing, resulting in higher system performance

PX Q Series Flow Rates

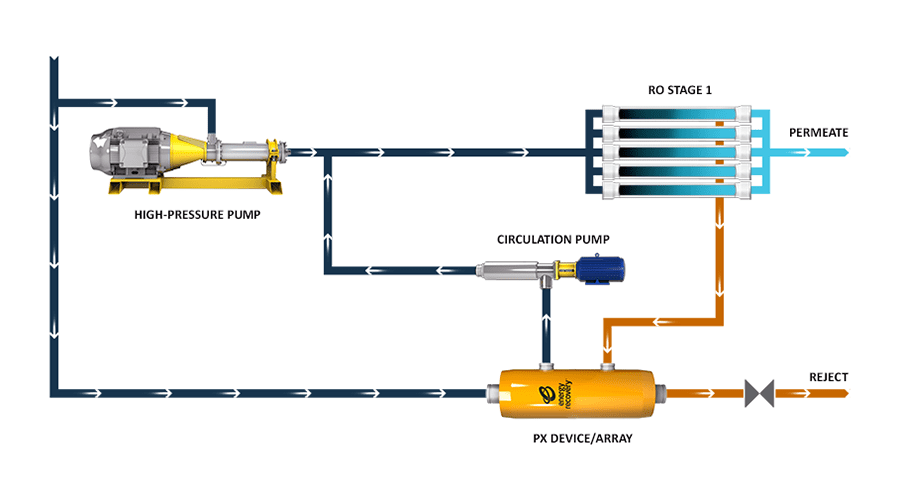

PX Q Series Integration*

*Example PX Q Series integration design. Actual configurations may vary.

Energy Recovery’s PX Q series recycles the wasted pressure energy from the concentrate stream of the SWRO or wastewater treatment plant and returns that pressure energy back to the system, reducing overall energy costs.

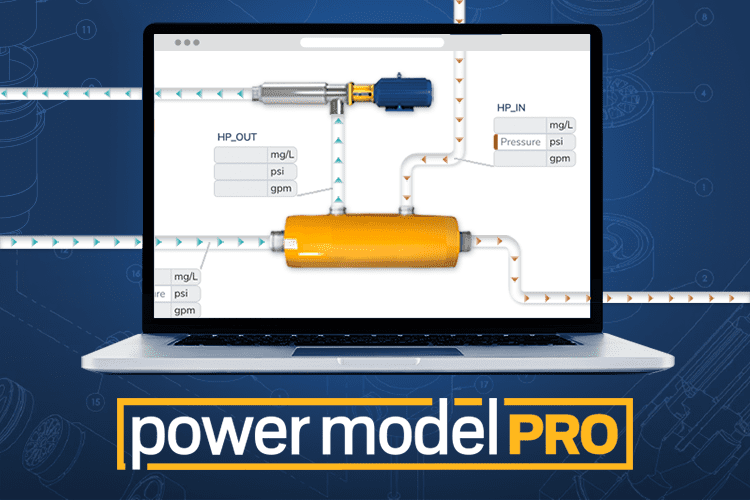

Power Model Pro

Power Model Pro is a secure, easy-to-use cloud-based product configurator tool that allows you to optimize the hydraulic pumping system of a reverse osmosis system using our products.

PX PowerTrain

The PX PowerTrain™ pre-engineered energy recovery solution combines Energy Recovery’s trusted PX® Pressure Exchanger® devices with frame support and ancillary equipment into a compact, ready to install high-performance energy recovery device array package for your seawater reverse osmosis train.

All-in-one

When coupled with our SWRO pumps, a complete end-to-end ERD solution.

Flexible

Pre-designed ERD and frame support for ease of installation, and 3D models are available for easy integration into plant design.

Big Projects

Train production capacity starting from 3000 CMD.

Streamlined

Work with a single trusted supplier from design to installation.

Related Industries

Building a more sustainable future where energy efficiency drives operational profitability.