On-demand Webinars and Podcasts

Currently less than 10% of wastewater is reused globally* but governments around the world are starting to implement policies to increase its adoption, such as setting reclaimed water targets, providing incentives for water reuse projects, and developing standards for treatment and reuse.

Advances in water treatment technologies such as advanced filtration, membrane technologies, and disinfection methods have improved the quality of treated wastewater. Triple barrier methods are even able to remove dissolved salts and so-called “forever chemicals,” or per- and polyfluoroalkyl substances (PFAS), from wastewater, making it suitable for drinking and irrigation. However, triple barrier technologies can also be energy intensive. Energy Recovery solutions help capture and save energy—and operating costs—in these water-saving processes.

Including our gold-standard PX Q series, our high-pressure PX products provide unmatched energy recovery for large and small seawater reverse osmosis (SWRO) desalination and water treatment systems.

Ideal for brackish water reverse osmosis and water reuse in municipal and industrial applications, our low-pressure PX solutions offer substantial energy savings and ease of integration.

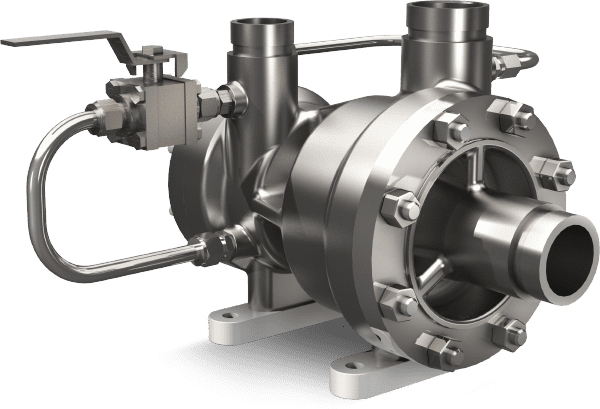

The AT turbocharger is an efficient, versatile, and reliable solution designed with a compact footprint—no instrumentation or additional equipment is necessary. In addition, it requires minimal installation time and operator training. With the turbocharger’s completely removable and replaceable hydraulics, plant staff can quickly and inexpensively change operating conditions as needed while...

On-demand Webinars and Podcasts

Brochure

Press Release

SAN LEANDRO, Calif. – May 21, 2025 — Energy Recovery (NASDAQ: ERII) today reported contract awards totaling over $7 million for its PX® Pressure Exchanger® (PX) energy...

Press Release

SAN LEANDRO, Calif. – Feb. 27, 2025 — Energy Recovery, Inc. (Nasdaq: ERII) today announced the results of recently conducted testing which concludes that the PX® Pressure®...

Press Release

SAN LEANDRO, Calif. – Feb. 26, 2025 — Energy Recovery, Inc. (Nasdaq: ERII) today announced its Board of Directors approved a share repurchase program to purchase up to $30...

Press Release

SAN LEANDRO, Calif. – Feb. 26, 2025 — Energy Recovery, Inc. (Nasdaq: ERII) today announced the appointment of a new Chief Technology Officer and Vice President, Wastewater....