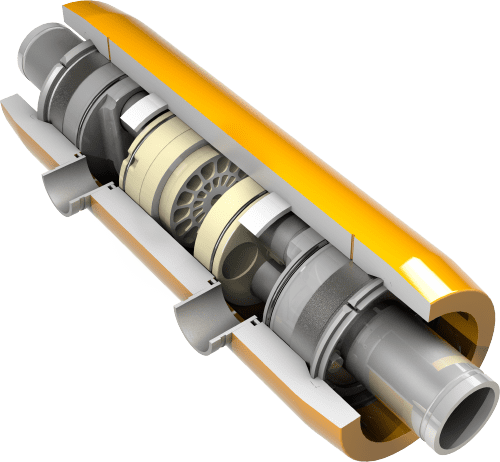

PX® Pressure Exchanger® (PX) energy recovery devices (ERDs) manufactured by Energy Recovery, Inc. are designed and built for long-term reliability and safe performance. PX devices contain no wear parts and require no routine maintenance. With careful choice of materials, robust designs developed using advanced computational and analytical tools, precision manufacturing, and rigorous inspection and validation testing, PX devices in seawater reverse osmosis applications are built for several decades of operating life.

This paper provides a thorough assessment of PX device design, construction, and performance characteristics as they relate to reliability and design life. Specifically, it lists and analyzes materials of construction, design standards, fatigue assessments, quality control procedures and data, customer return information, and strength and durability tests on both new and long-running PX devices.

Results

The fatigue life analyses demonstrated that PX components can be operated through full-pressure cycles for 30 years* without material fatigue. In addition, fatigue fracture analyses and vendor data from all procured parts show that all the components can last for at least 30 years when operated as per specifications. No PX unit has been returned by a customer for design or manufacturing defects. As part of this whitepaper analysis, two PX Q300 devices that had operated continuously for over a decade in the field were tested, disassembled, and analyzed. This showed that the units and their components remained in their original condition, with no signs of life-limiting wear or damage.

*Disclaimer: Assuming proper operation of PX designed for pressures of 1,200 psi (82 bar) or less in seawater reverse osmosis applications.

To find out more, read the full whitepaper at the link below.