Membrane filtration with ERDs

Lithium extraction often relies on evaporation, which can require vast amounts of energy, land, and time. Increasing regulations are now mandating lithium ore mines and battery production facilities to treat their wastewater, which is an energy intensive process. Membrane technology, in conjunction with energy recovery devices (ERDs), can vastly reduce the electricity, steam, land, and other resources required to produce lithium ion batteries compared to traditional methods, reducing or replacing lengthy evaporation periods in lithium extraction.

This technology can also more efficiently clean wastewater produced by lithium mining, refining, and battery production, addressing pain points along key areas of the supply chain. Over traditional thermal and solar evaporation, membrane filtration with ERDs offers a lower equipment CAPEX, reduced energy consumption, smaller footprint, and significantly shorter production time.

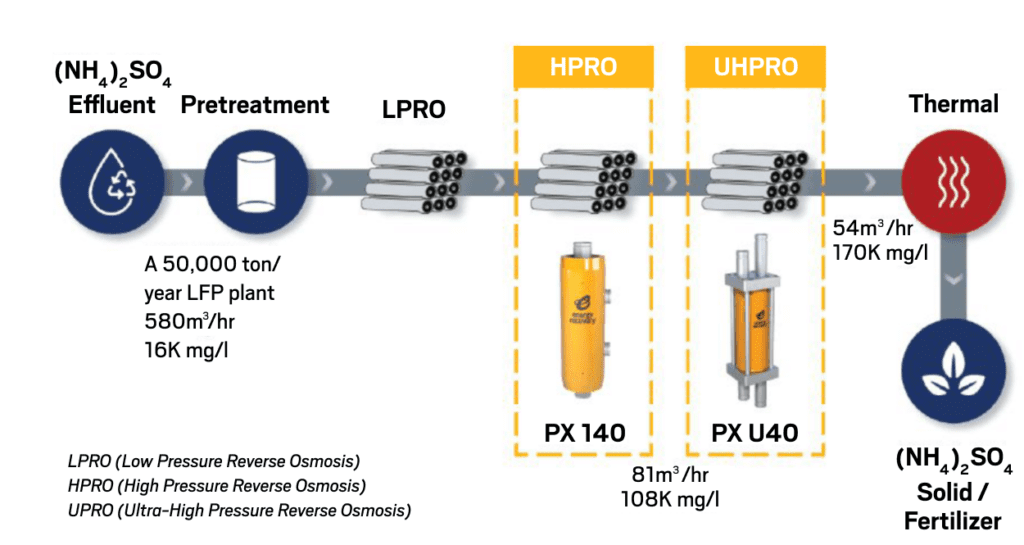

Another driver is that many waste streams contain valuable ions that can be reused or resold. At many cathode manufacturing facilities, RO systems with PX technology are used to cost effectively turn cathode manufacturing waste streams into solid fertilizers (e.g., ammonium sulfate or ammonium phosphate) or other valuable commodities (e.g., sodium sulfate) depending on cathode chemistry which are then sold to help offset the cost of the treatment system.

Featured Products

High-Pressure PX

Including our gold-standard PX Q series, our high-pressure PX products provide unmatched energy recovery for large and small seawater reverse osmosis (SWRO) desalination and water treatment systems.

Low-Pressure PX

Ideal for brackish water reverse osmosis and water reuse in municipal and industrial applications, our low-pressure PX solutions offer substantial energy savings and ease of integration.

Ultra High-Pressure PX

The key to lower energy use in wastewater treatment and reuse for ultra high-pressure applications, helping make zero and minimal liquid discharge (ZLD and MLD) low-cost and energy-efficient.

Resources

On-demand Webinars and Podcasts

Making Lithium Sustainable with Innovative Energy Recovery Solutions

Upcoming Events

Interested in Meeting Us?

Find an EventLook here for the latest information on our upcoming conferences, webinars, meetings, and other events.

Find an EventRecent News

Press Release

Energy Recovery Announces $32.8 Million in...

SAN LEANDRO, Calif. – November 17, 2025 — Energy Recovery (NASDAQ: ERII) today announced significant project wins in Saudi Arabia, with multiple PX® Pressure Exchanger® (PX)...

Press Release

New Data from Supermarket Installations Show...

SAN LEANDRO, Calif. – October 29, 2025 — Energy Recovery (Nasdaq: ERII) today released recent data from CO2 refrigeration installations across North America and Europe that...

Press Release

Energy Recovery Awarded $31 Million in...

SAN LEANDRO, Calif. – September 3, 2025 — Energy Recovery (NASDAQ: ERII) recently reported contract awards totaling approximately $31 million for its PX® Pressure Exchanger®...

Press Release

Energy Recovery Announces Desalination Contracts Totaling...

SAN LEANDRO, Calif. – May 21, 2025 — Energy Recovery (NASDAQ: ERII) today reported contract awards totaling over $7 million for its PX® Pressure Exchanger® (PX) energy...