UHP Circulation Pump

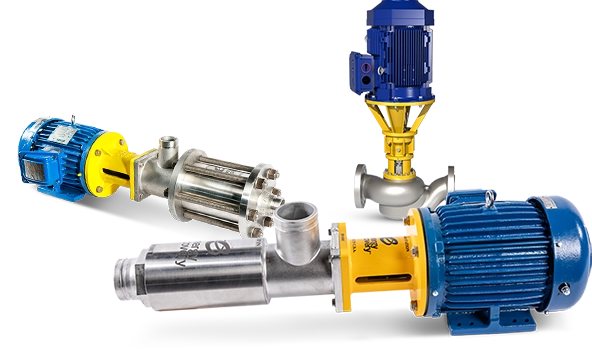

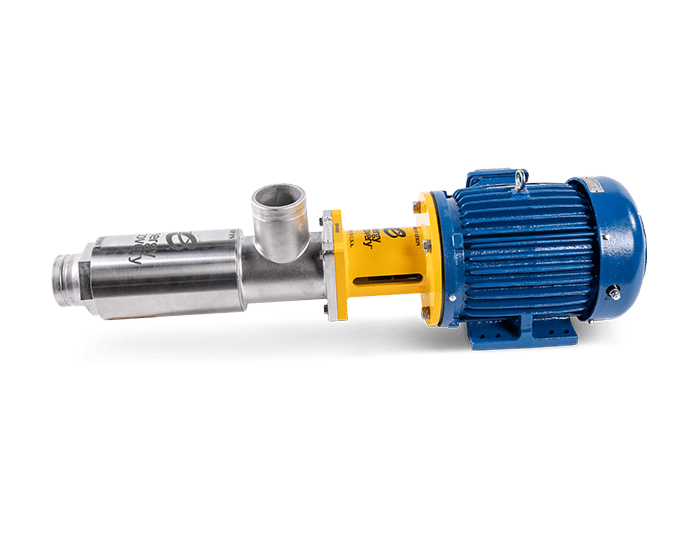

Our low-flow horizontal pumps pair with our PX devices for high-pressure RO trains with permeate production rates ranging from approximately 135 to 1,350 m3/day (35K to 356K gpd).

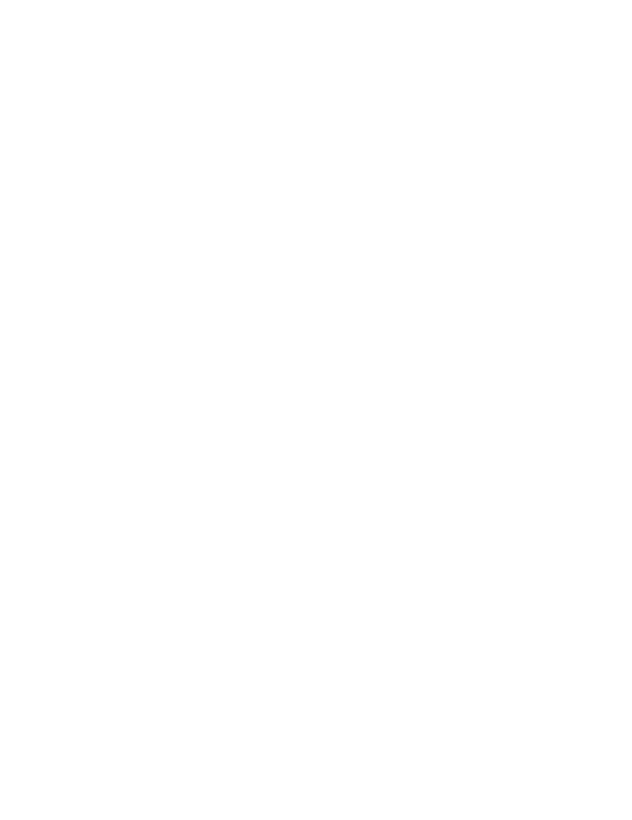

Our line of high-pressure membrane feed and PX® Pressure Exchanger® circulation pumps are built with corrosion-resistant material—yielding a long and reliable service life—and designed specifically for high-pressure reverse osmosis (RO) applications. Because uptime matters.

Our low-flow horizontal pumps pair with our PX devices for high-pressure RO trains with permeate production rates ranging from approximately 135 to 1,350 m3/day (35K to 356K gpd).

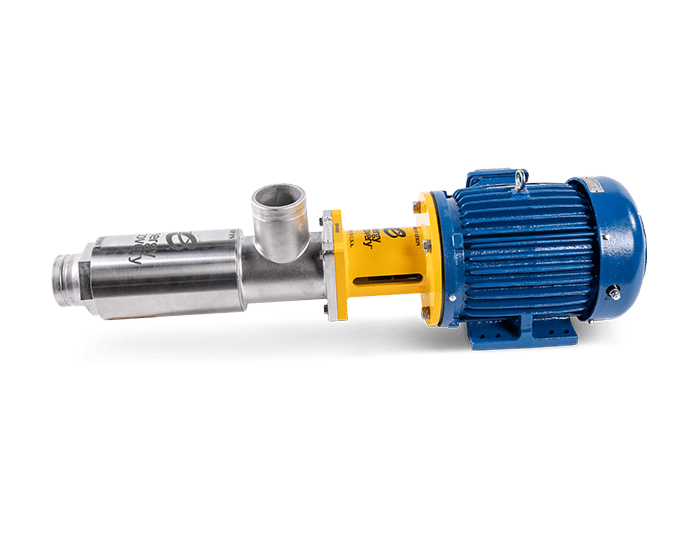

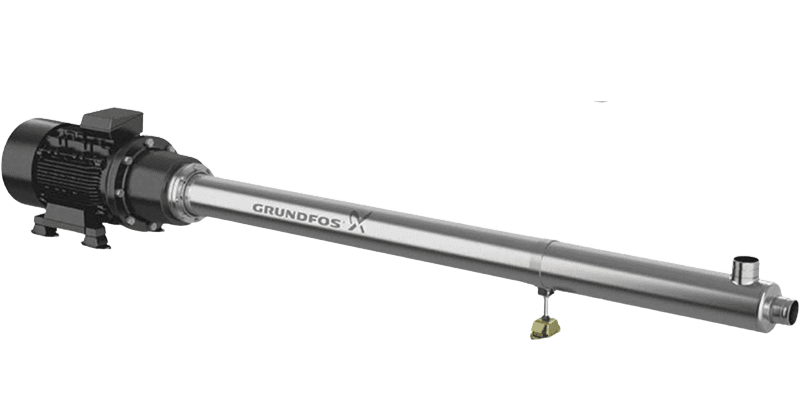

Our high-flow vertical pumps target high-pressure RO plants with permeate production rates ranging from 640 to 10,000 m³/day (168K to 2.64M gpd). To optimize energy recovery, our circulation pumps pair with our PX devices for an end-to-end energy recovery solution that maximizes efficiency and cost savings.

Our low-flow horizontal pumps pair with our PX devices for high-pressure RO trains with permeate production rates ranging from approximately 135 to 1,350 m3/day (35K to 356K gpd).

Energy Recovery offers the ATMP high-pressure pump, a high speed, multistage feed pump ideal to combine with the Energy Recovery PX® Pressure Exchanger® or the AT Turbocharger energy recovery device. ATMP is ideal for small to medium-scale reverse osmosis systems where reliability matters.

We’ve invested years of research and development to build versatile solutions that meet the demands of any size water project or environment, offering high efficiency and performance.

Designed to be used in combination with our PX devices in seawater reverse osmosis, brackish reverse osmosis, or wastewater treatment plants, our circulation pumps offer high efficiency and performance.

High-pressure pumps force feedwater to pressures required by the reverse osmosis membranes. Our high-pressure pumps can deliver pressures up to 83 bar (1,200 psi). They are designed using corrosion-resistant stainless steel alloys to stand up to the operational and environmental demands of a high-pressure RO system.

Building toward a more sustainable future where energy efficiency drives operational profitability across a growing range of industries.