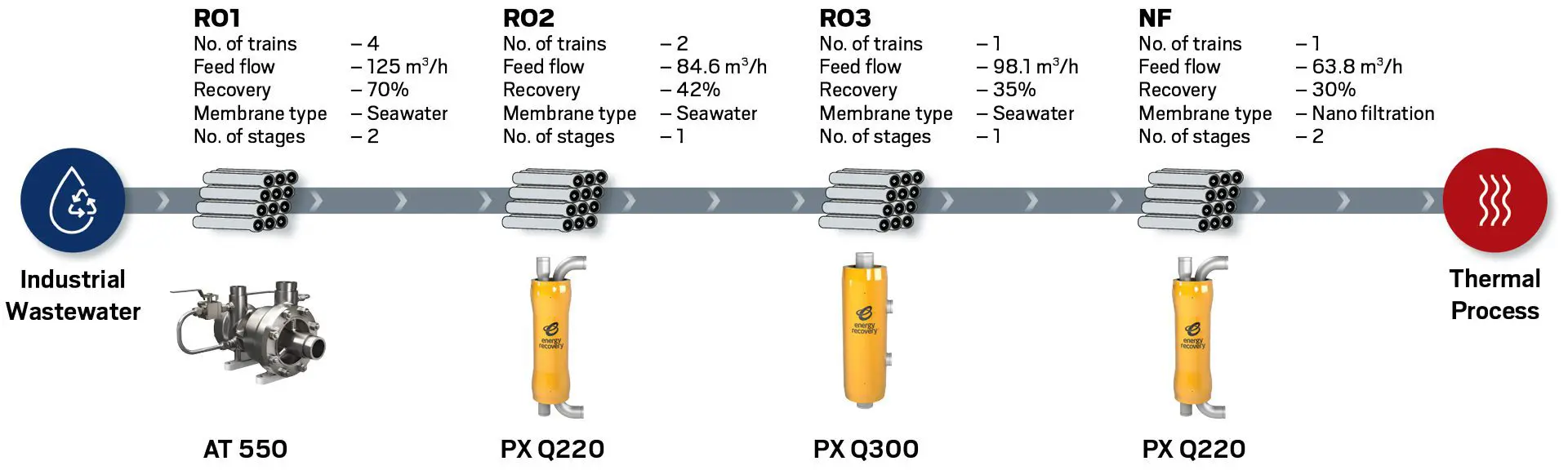

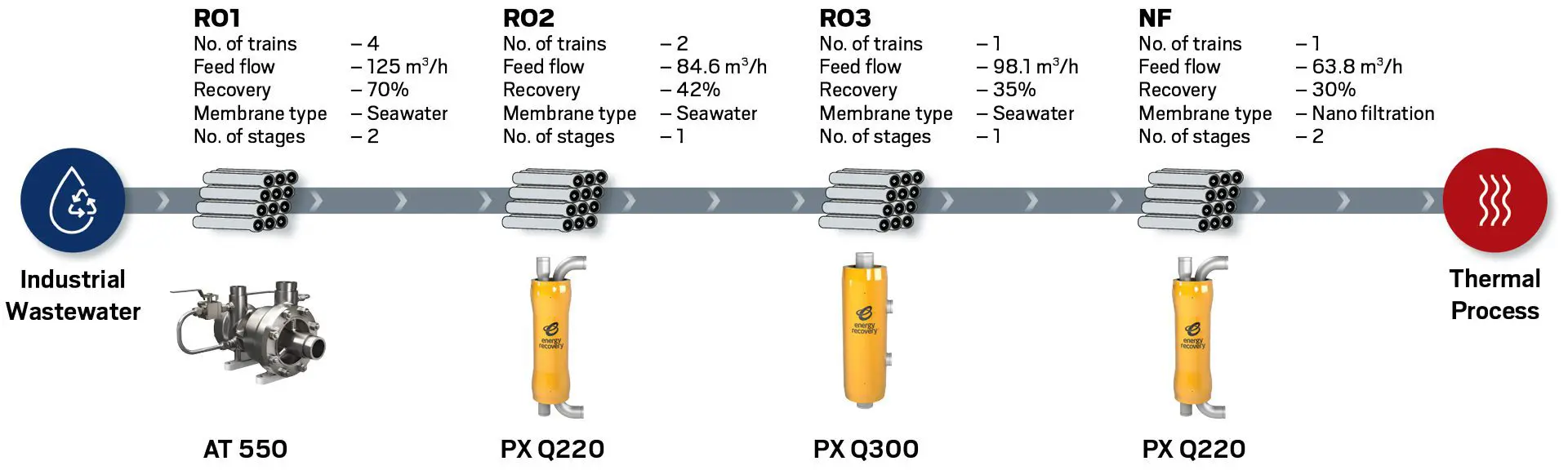

The Pali Common Effluent Treatment Plant in Pali, Rajasthan, India supports 215 factories located in the surrounding Punayata Industrial Area. All the equipment in the plant is supplied by Aldee Water Pvt. Ltd. Advanced reverse osmosis water treatment was adopted to significantly reduce the stream volume being sent to the thermal system, reducing both CAPEX and OPEX of the thermal system. With added nanofiltration processes in place to separate salt, the high purity salt could then be recycled and sold.

To achieve more efficiency and cost savings, Detox Group and Pali CETP partnered with Energy Recovery, Inc. to install a suite of energy recovery devices, including both turbochargers and pressure exchangers, bringing higher uptime and availability to the whole system.

The plant now utilizes the following Energy Recovery products: AT Turbocharger, PX Q300s, PX Q220s, AquaBold high-pressure pump, and HP and VPXP circulation pumps.

The goal was to achieve high recovery rates in the membrane trains to minimize the brine flow into an evaporator to meet minimal or zero liquid discharge regulations. This required multiple reverse osmosis systems in conjunction with nanofiltration.

Energy Recovery’s solutions accommodate wide flow and pressure operating ranges

The textile waste stream parameters from 215 textile manufacturing businesses can pose a challenge, leading to wide flow and pressure operating ranges for the RO process. The challenge was met with a full complement of Energy Recovery products proven to perform in these demanding conditions, achieving maximum plant savings and energy efficiency.

The PX devices with a suite of companion pumps provided operational flexibility and was the ideal solution for the Pali CETP plant.