Mining

Globally, mining facilities are looking to lower the energy use of producing acceptable feedwater for mining and treating wastewater to prevent harmful discharge from acid mine drainage and tailing ponds.

Learn MoreReduce the specific energy footprint of producing clean water with reverse osmosis by 30–60% today, and accelerate the path toward net-zero water treatment. Our solutions deliver significant energy and cost savings across all pressure levels and plant sizes.

94%

Peak efficiency of U Series

98%

Peak efficiency of PX devices

60%

Peak energy savings from recovering wasted energy

22.5M

Metric tons of carbon emissions avoided by our customers annually

Globally, much of the wastewater that is generated is discharged into the surrounding environment without treatment. As climate change and drought are stressing today’s water supply, treating and reusing wastewater efficiently is essential to avoid harmful discharge and provide new sources of water.

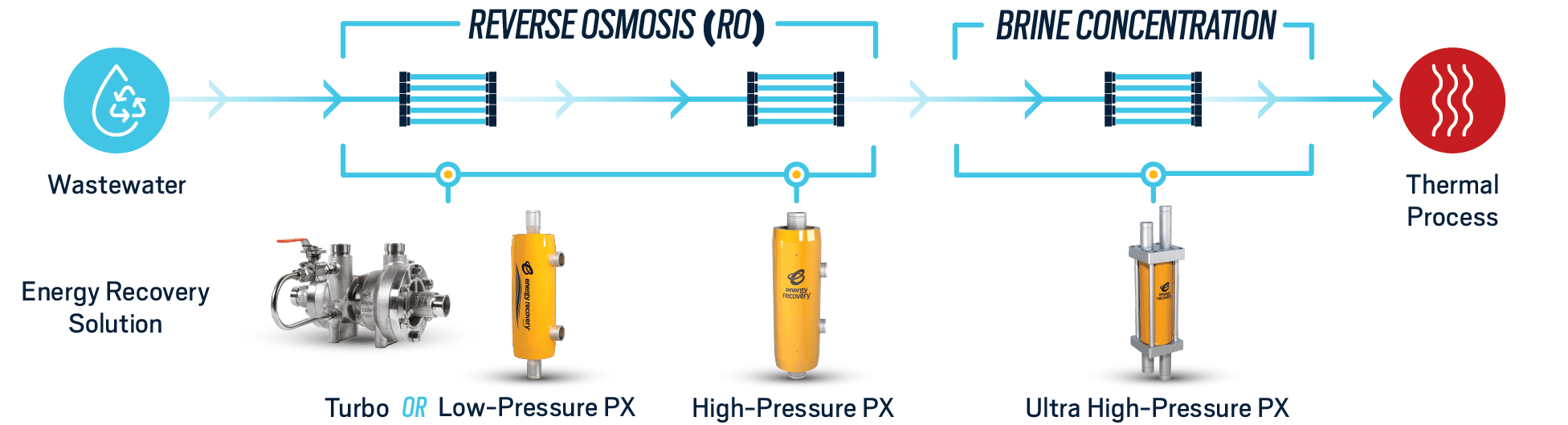

Energy Recovery’s suite of products optimizes the energy consumption of reverse osmosis in municipal and industrial wastewater systems and reduces the associated carbon emissions.

We offer low, high, and ultra high-pressure energy recovery devices suitable for any size plant or multiple stages of a membrane-based wastewater treatment system with pressures of up to 120 bar (1,740 psi).

By integrating the PX into our high-pressure concentration process, we were able to reduce energy consumption in that process by 45%, making PX payback less than one year.

Mr. Wu Yong Dong, QingXu Plant Manager