Brackish Water RO Systems

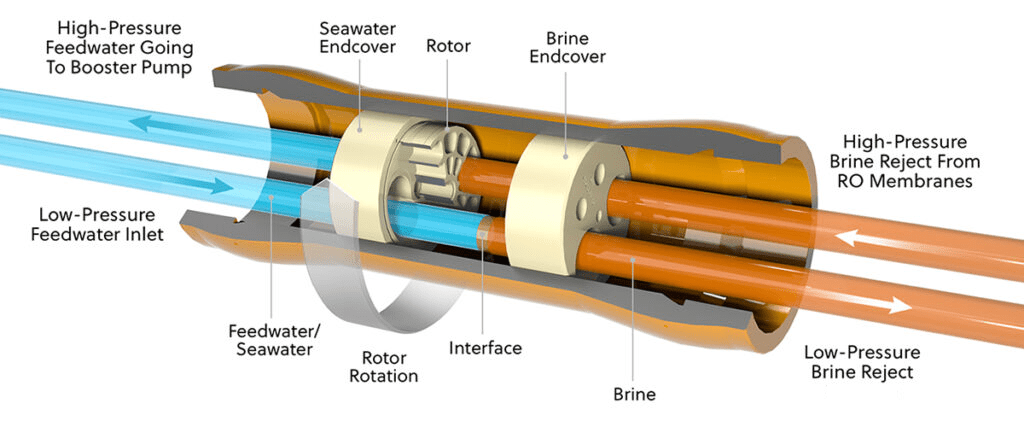

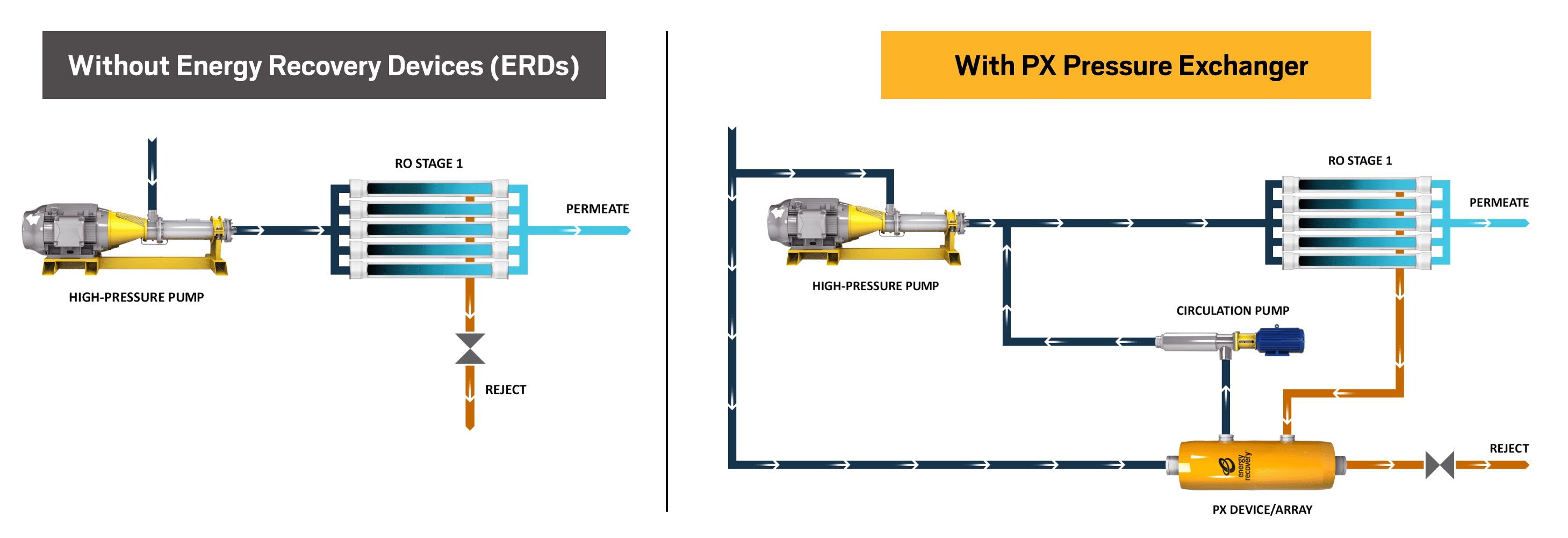

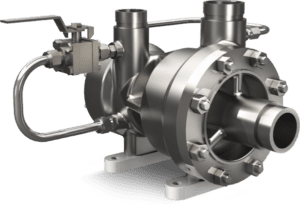

Brackish water reverse osmosis (BWRO) systems are increasingly critical for treating challenging water sources in industrial and municipal operations. These systems demand high energy input, driving up operational costs—especially at scale. Energy Recovery’s PX® Pressure Exchanger® technology delivers a high-efficiency solution, significantly reducing energy consumption and improving cost-effectiveness in brackish water desalination. Whether treating produced water, surface water, inland brackish groundwater, or industrial wastewater streams, PX technology enables efficient, sustainable operations—even under fluctuating feedwater conditions.

Learn More