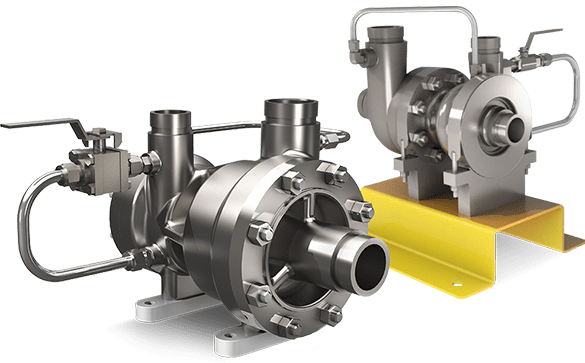

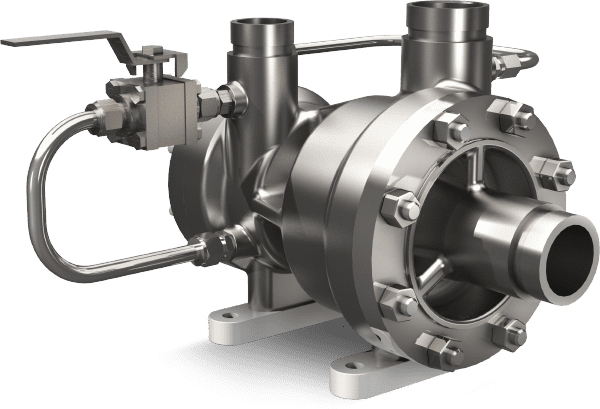

Perfected for High-Pressure Environments

The AT turbocharger is an efficient, versatile, and reliable solution designed with a compact footprint—no instrumentation or additional equipment is necessary. In addition, it requires minimal installation time and operator training. With the turbocharger’s completely removable and replaceable hydraulics, plant staff can quickly and inexpensively change operating conditions as needed while maintaining facility uptime.

This modular technology consists of pump and turbine volutes, a turbine nozzle and pump-side discharge diffuser. Ideal for any size SWRO system, the AT Turbocharger handles flows from 11 to 2,272+ m3/h (10,000+ gpm) and pressures from 27 to 83 bar (400 to 1,200 psi). For a centrifugal solution, the innovative volute insert technology allows systems to perform within a best efficiency range rather than at a single best efficiency point. If system conditions change, requiring a new operating point, these lightweight inserts can be removed and replaced in hours instead of days or even weeks, maximizing facility uptime.