Case Study / Desalination / Wastewater

Energy Recovery’s low-pressure PX® Pressure Exchanger® can drive operational efficiency in clean water production for low-pressure systems, providing a sustainable path to saving operational energy. By reducing the energy consumption of low-pressure reverse osmosis, our PX solutions reduce the emissions associated with industrial and municipal reuse, enabling a circular water economy and preventing harmful discharge into the environment. The low-pressure PX is designed for brackish water reverse osmosis (BWRO) and wastewater reuse applications, operating at low pressures up to 31 bar (450 psi) and is ideal for use in small and large municipal and industrial plants, making the production and recycling of water financially and environmentally sustainable.

99.8%

Industry-leading uptime and reliability

30 Years

Designed to last with no scheduled maintenance

450 PSI

Maximum pressure

97%

Peak efficiency

The PX Pressure Exchanger transfers hydraulic energy from the concentrated brine stream and uses it to supplement the flow from the main high-pressure feed pump, which feeds the membranes. This is done via direct contact between the concentrated brine and filtered seawater feed stream. An optional booster pump can be used to balance the fluxes in both stages.

Industry-leading reliability and no scheduled maintenance

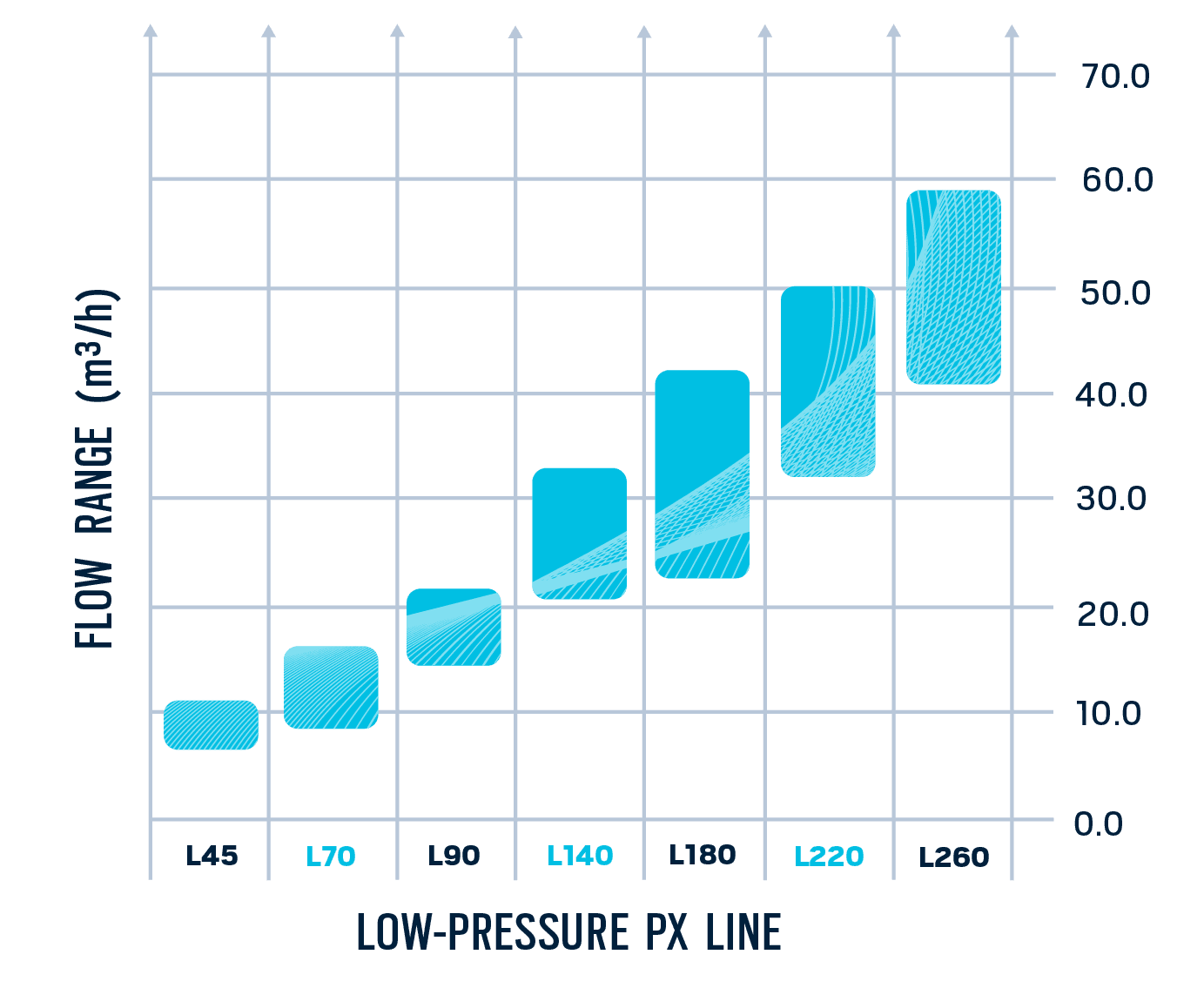

Modular and scalable isobaric device with wide operating range

Short payback period

Potential to use in existing feed and booster pumps

Lower the energy consumption of wastewater treatment for reduced greenhouse gas emissions

Case Study / Desalination / Wastewater

Brochure / Desalination / Wastewater

Brochure / Desalination / Wastewater

Building a more sustainable future where energy efficiency drives operational profitability.