Sustainability Report

Sustainability Report

Case Study / White Paper / Desalination / Wastewater

As the world faces the hard reality of climate change and ever-worsening water scarcity, the need to leverage unconventional water...

Case Study / Desalination

Across the globe, the challenge of securing clean water while reducing energy consumption has pushed the boundaries of desalination...

Brochure / Desalination / Wastewater

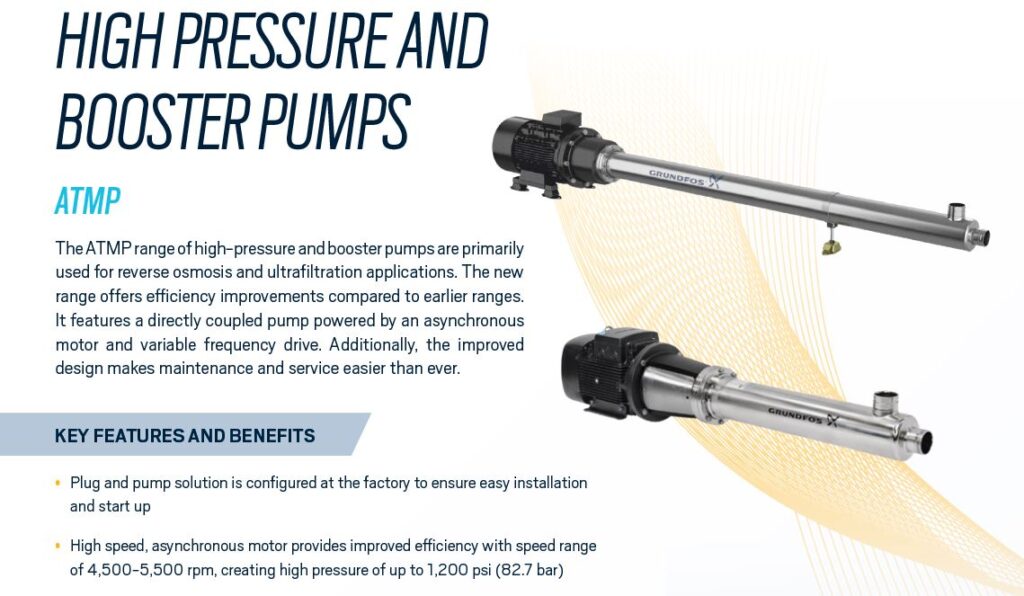

The ATMP range of high-pressure and booster pumps are primarily used for reverse osmosis and ultrafiltration applications. The new range...

Video & Animation / Desalination

Belén Gutiérrez Lopez, Head of Desalination Area R&D at GS Inima, shares her insights on the PX® Pressure Exchanger®—highlighting...

Video & Animation / Desalination

Alessio Voena, Senior Process Engineer at Fisia Italimpianti, shares why he confidently recommends Energy Recovery and the PX® Pressure...

Brochure / Desalination

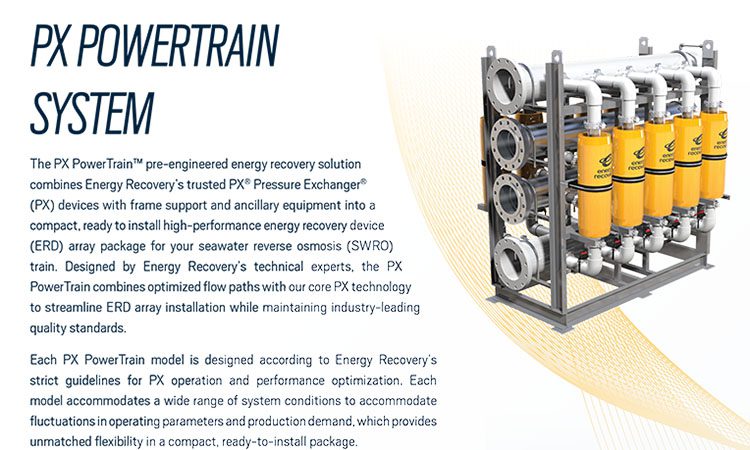

The PX PowerTrain™ pre-engineered energy recovery solution combines Energy Recovery’s trusted PX® Pressure Exchanger® (PX) devices...

Video & Animation / Desalination

Gary Crisp, Chief Engineer at Sequana Partners, was one of the first to embrace Energy Recovery’s pressure exchanger technology. Over two...

Video & Animation / Desalination

Moustafa Essam Daoud, Chief Executive Officer at ProServe Egypt, tells us about his 20-year relationship with Energy Recovery and the PX®...

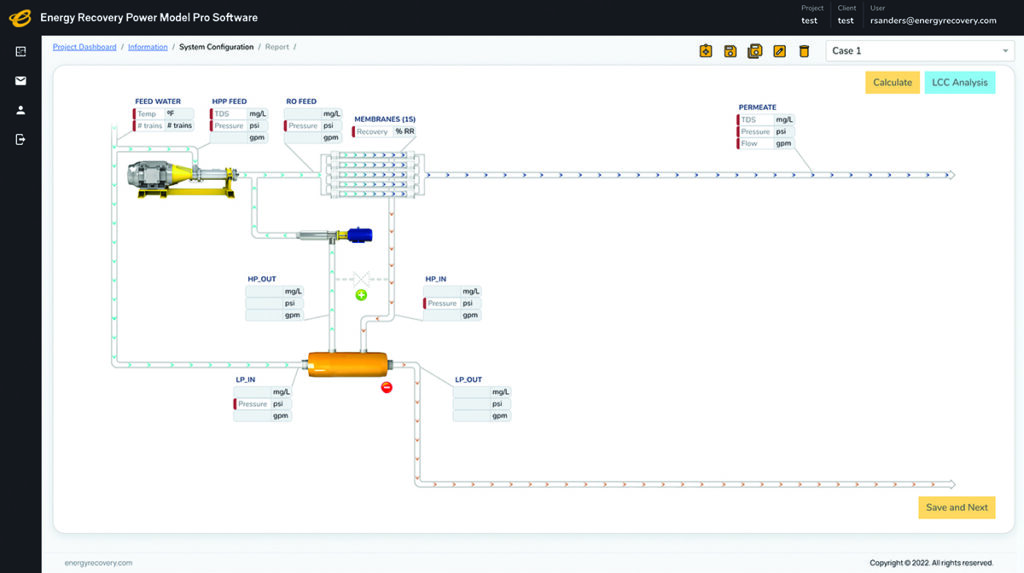

Tools & Apps / Desalination / Wastewater

A cloud-based configuration tool to plan for industrial wastewater or desalination projects Helping you build customizable projects and...

Case Study / Desalination

Redesigning a Potable Water Treatment Facility to Remove Contaminants While Saving Energy A potable water treatment facility located along...

Case Study / Wastewater

The Lubei Wanrun Intelligent Energy Plant is an LFP cathode manufacturing facility in Binzhou, a city in the Northern part of Shandong...